One reason so many are quitting: We want control over our lives again

The pandemic, and the challenges of balancing life and work during it, have stripped us of agency. Resigning is one way of regaining a sense…

Thought Leader: Amy Cuddy

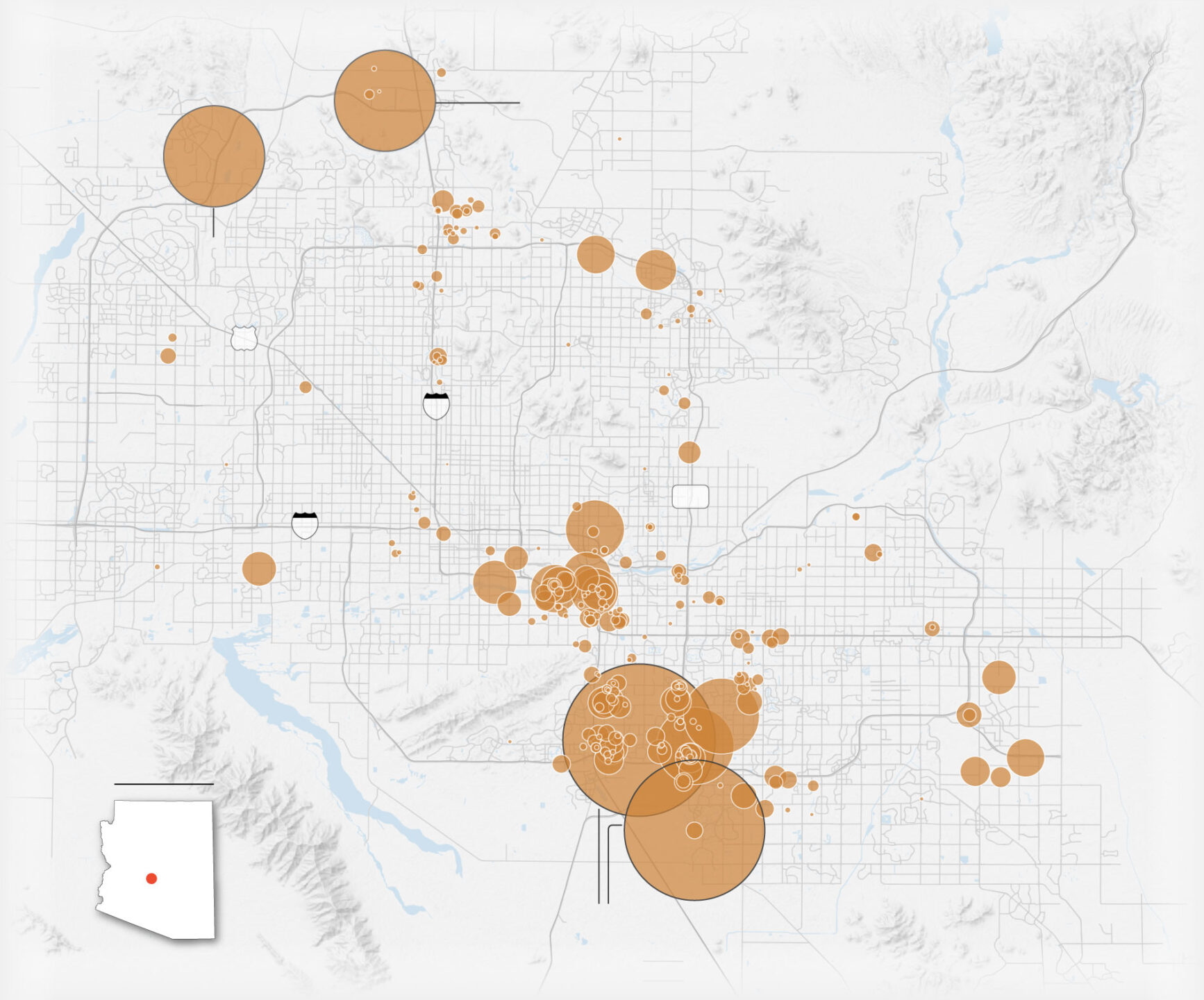

In a sweeping examination of America’s race to rebuild its semiconductor capacity, Peter Goodman explores how a barren stretch of the Sonoran Desert has become the unlikely epicenter of one of the most ambitious industrial projects in U.S. history. Rising out of 1,149 acres north of Phoenix is a $165 billion network of cutting-edge chip factories led not by an American company, but by Taiwan Semiconductor Manufacturing Company (TSMC)—the global titan behind the world’s most advanced chips.

The vision is bold: secure a domestic supply of the “brains” that power everything from artificial intelligence to national defense, while insulating the U.S. from geopolitical shocks. Yet the reality on the ground reveals a far more complicated story.

Goodman shows how the Phoenix project has become a test case for America’s industrial aspirations—and the many obstacles standing in the way. Even with TSMC’s expertise and billions in subsidies through the CHIPS and Science Act, the U.S. lacks the recent experience, regulatory clarity, and skilled workforce required to build advanced chip facilities at scale.

The challenges are staggering:

• A maze of bureaucracy: Unlike Taiwan’s streamlined system, TSMC must navigate thousands of municipal, county, state, and federal permits—many for processes that don’t even exist in local codes.

• Labor shortages: The U.S. simply doesn’t have enough workers with the specialized skills chip manufacturing requires, forcing TSMC to fly in experienced teams from Taiwan and triggering labor tensions.

• Cultural clashes: Differing workplace expectations—TSMC’s fast-moving, top-down model vs. American norms around hours, rights, and safety procedures—have strained operations and sparked lawsuits.

• Cost overruns: Building in the U.S. is proving far more expensive than TSMC warned, raising concerns about long-term competitiveness.

• Community pushback: Nearby residents, wary of chemicals, water consumption, and industrial sprawl, have successfully fought off some supplier facilities.

Despite all this, progress continues. One TSMC factory is already up and running, with two more under construction and additional fabs and packaging facilities planned. Surrounding the site, a web of suppliers—many from East Asia—has invested over $40 billion, while developers plan entire new neighborhoods, retail centers, and industrial zones to support the growing “Silicon Desert.”

The geopolitical backdrop looms large. TSMC’s move was prompted in part by U.S. pressure and customer concerns about the vulnerability of Taiwan—claimed by China and central to global chip supply. Companies like Apple and Nvidia pushed TSMC to build on U.S. soil, viewing Arizona as a hedge against conflict in the Taiwan Strait.

Goodman underscores a central irony: America is racing to onshore chip production, yet its success depends almost entirely on the expertise and ecosystem Taiwan has spent decades perfecting. Recreating that environment in the U.S. requires more than subsidies; it demands rethinking regulation, training, industrial strategy, and how America builds things.

The article ultimately illustrates both the promise and the friction of a new industrial era—one where chips drive global power, and where the U.S. must confront its own structural barriers if it wants to lead. As Nvidia’s Jensen Huang told workers at the Phoenix site, “This is a very big day for America… This is only the beginning.” But as Goodman makes clear, the road ahead is neither simple nor assured.

Read the full New York Times article here.

Peter S. Goodman is a standout keynote speaker on global economics, trade policy, and financial markets, known for his ability to translate complex economic shifts into clear, compelling narratives. Goodman offers a vital perspective on the geopolitical and economic consequences of policy chaos, making him an essential voice for audiences seeking to understand the fragility of markets in an age of uncertainty. His speaking engagements are managed exclusively by WWSG. To host him for your events, contact us.

One reason so many are quitting: We want control over our lives again

The pandemic, and the challenges of balancing life and work during it, have stripped us of agency. Resigning is one way of regaining a sense…

Thought Leader: Amy Cuddy

Molly Fletcher: Can drive offset your burnout at work?

This piece is by Molly Fletcher. People assume that drive depletes energy. They believe that level of intensity, focus and daily effort leads to burnout.…

Thought Leader: Molly Fletcher

Loretta Mester: Fed most likely to cut rates by quarter point

Former Cleveland Fed president Loretta Mester joins CNBC’s ‘The Exchange’ to discuss her expectations for rate cuts, whether the Fed’s focus should be on rates…

Thought Leader: Loretta Mester