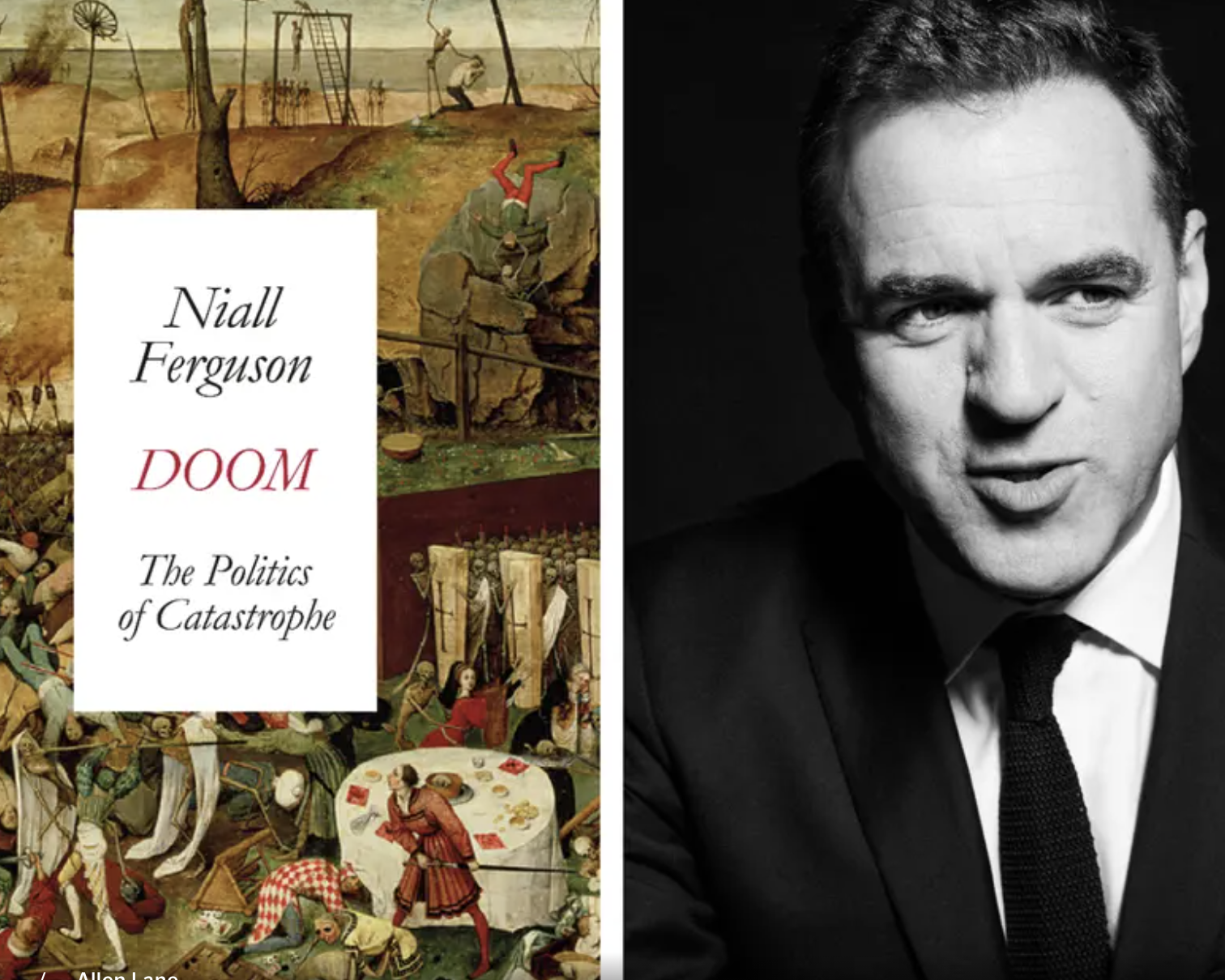

Doom: The Politics of Catastrophe by Niall Ferguson review

(Evening Standard) – From plagues and volcanic eruptions to the current Covid pandemic, mankind has always been faced with catastrophes.

Thought Leader: Niall Ferguson

From Patrick McGee: The problem with building iPhones in America isn’t that they’d be priced at $3,500 each. It’s that they wouldn’t be built at all.

No need to run to the Apple Store after all. The iPhone and other major electronics were spared President Donald Trump’s “reciprocal tariffs”—including 125 percent import levies on China—in an opaque notice from U.S. Customs and Border Protection on Friday.

Although Trump denied on Sunday that the notice left anybody “off the hook” and said, via Truth Social, that the “the WHOLE ELECTRONICS SUPPLY CHAIN” would be subject to a new “bucket” of tariffs, it’s nevertheless the case that electronics made in China are, for the moment, subject “only” to 20 percent tariffs.

It’s anyone’s guess where the tariffs will be next week, let alone in three months. The uncertainty this causes for businesses and consumers is galling. Were Apple to issue a revenue warning based on the tariff risk, what numbers would it use in their calculations? The administration’s policies are creating such whiplash that Apple could just as plausibly raise revenue guidance this quarter as American consumers rush to buy iPhones on fears of higher prices and product shortages.

What’s certain is that the U.S. and China both need Apple to succeed, albeit for very different reasons. The world’s most valuable company now finds itself caught in a cold war between two superpowers that want a divorce but need to make it work for their kid.

For Washington, Apple is a symbol of tech might. It is the world’s most valuable company, and one that generates great wealth for its (largely American) stockholders.

The prospect of Apple losing a trillion dollars of value, as it did in a matter of weeks before Trump offered a 90-day pause to most tariff actions last week (China excluded), would impact virtually everyone with a 401(k) account.

In China, Apple is the Great Teacher. For a quarter-century, the tech giant has made massive investments in equipment and sent thousands of its top engineers to hundreds of factories across the country, training China’s workers how to meet near-impossible engineering standards and then scale production to enormous volumes.

By CEO Tim Cook’s estimate, Apple’s Chinese suppliers employ 3 million people. Were Apple to move its operations to another country, China would sustain major job losses. Perhaps even worse, it would miss out on the cutting-edge lessons that continue to make it the world’s preferred hub for tech manufacturing.

Washington has legitimate reasons for wanting to bring tech manufacturing back to the U.S., but Trump administration officials like Commerce Secretary Howard Lutnick are woefully out of touch in suggesting there is some near-term fix. They behave as though Apple moving its supply chain is a matter of willpower and cost. But the problem with building iPhones in America isn’t that they’d be priced at $3,500 each; it’s that they wouldn’t be built at all.

A smart reader might retort, “Not true! Look at Tesla’s state-of-the-art manufacturing in Texas.” But this argument fails to grasp the sheer scale of Apple’s production.

Each iPhone is made from 1,000 components. For Apple to ship one million units a day requires hundreds of factories in China to build one billion parts per day. It’s one of the most complex supply chains on Earth. And that’s just for the iPhone. The nightmarish complexity multiplies if you include iPads, MacBooks, Macs, AirPods, and AirTags. Apple ships more products on a busy day than Tesla ships in an entire year.

Moreover, American workers wouldn’t put up with the soul-crushing work that Apple’s supply chain requires.

Consider that in 2014, a Shanghai-based factory run by the Taiwanese supplier Pegatron employed 100,000 laborers; at times the company was losing 25,000 workers a month, according to a former China-based Apple executive. This meant that “they needed to hire 25,000 just to stay in a steady state,” he related. A contemporaneous “attrition memo” from Apple corroborated this, saying: “Worker exit rates at Pegatron Shanghai averaged 6 percent per week, and average tenure was only 68 days.” (It’s not hard to grasp why: These jobs are often 12 hours a day, 6 days a week of tremendously monotonous work.)

If the Trump administration were serious about moving a substantial portion of iPhone production to America, it would need to transplant at least 20 percent of the China-centric supply chain workforce, said Michael Hillman, who spent 16 years overseeing hardware projects at Apple. That would entail creating a targeted visa program for 600,000 people.

Apple might run the world’s most sophisticated supply chain, but it has never made any logistical moves on such a scale. In 2011, Apple dealt with two major natural disasters: once-in-a-century floods in Thailand and the Japanese tsunami. Each disrupted the supply of critical components for weeks. By comparison, moving production for every component that makes up the iPhone would take years, if it were even possible.

“The building, the physical equipment—that’s the easy part,” Hillman said. “But human capital—the investment in people, the experiential knowledge—that’s the hard part.”

Needless to say, a targeted program to hire half a million Chinese workers wouldn’t fly with MAGA supporters—and Beijing could react in any number of ways to harm Apple.

Indeed, Beijing has quietly exerted its power in the past. When Xi Jinping took office in late 2012, Apple engineers found that rules limiting their stay in the country were suddenly enforced. Some even had to pay fines on the spot. At times, supplies moving from one Apple supplier to another hit inexplicable road blocks. A U.S. State Department official living in China at the time recalls that such inconveniences—known as bu fang bian in Mandarin—went from relatively rare, before Xi took over, to pervasive.

The Chinese government is in a position to make Apple’s diversification efforts painful. “They can lower the boom on you in a million different ways,” said Brady MacKay, a former U.S. special agent and attaché to the U.S. embassy in Beijing, who has seen the Chinese Communist Party deploy a number of tactics against other companies to make its point. “Like, raw materials—they can shut that off in a heartbeat,” he said. “Electricity—all of a sudden it’s only available four hours a day.”

Apple’s quarter-century consolidation into China has left it deeply vulnerable. While Cook likes to say the iPhone is “made everywhere,” alluding to how hundreds of suppliers originating from at least 40 countries contribute to its production, all roads lead through China. Even the phones labeled “made in India” are just assembled there—after extensive tooling, stamping, shaping, etching, and fitting of all the materials and parts in China.

Meanwhile, Apple’s engineering lessons to China’s top suppliers now face diminishing returns. The latest phones from homegrown champions Huawei and Oppo now match, and arguably exceed, the flagship devices from Apple. The student, as they say, is becoming the master.

Hillman, the 16-year Apple veteran, compared Beijing to “a Shaolin master who can incapacitate their adversary with just a two-finger pinch of a nerve cluster.” It’s a good analogy; unfortunately, erratic changes in policy are making Washington look more like Beverly Hills Ninja, the 1997 Chris Farley character remembered for striking himself in the groin with nunchucks.

Patrick McGee is the author of the forthcoming book, Apple in China: The Capture of the World’s Greatest Company.

Doom: The Politics of Catastrophe by Niall Ferguson review

(Evening Standard) – From plagues and volcanic eruptions to the current Covid pandemic, mankind has always been faced with catastrophes.

Thought Leader: Niall Ferguson

Time to end secret data laboratories—starting with the CDC

The American people are waking up to the fact that too many public health leaders have not always been straight with them. Despite housing treasure…

Thought Leader: Marty Makary

Sanjay Gupta: There are still key questions about Trump’s injuries after attempted assassination

This piece is by WWSG exclusive thought leader, Sanjay Gupta. It’s been five days since gunfire erupted at Republican presidential candidate Donald Trump’s rally in…

Thought Leader: Sanjay Gupta